CS Unitec Tools

Box End Wrench, 6-Point

CS Unitec’s Non-sparking tools and Non-magnetic hand tools are manufactured from special Aluminum-Bronze (AlBr) or Copper-Beryllium (CuBe) alloys for safe use in Ex zones and where hazardous, flammable or combustible vapors, liquids, dusts or residues may be present.

Request a QuoteFeatures

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2008 certified production, TUV materials certified.

- Non-sparking tool for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic tool for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant tool for use in desalination plants, chemical/paper manufacturing, and shipyards.

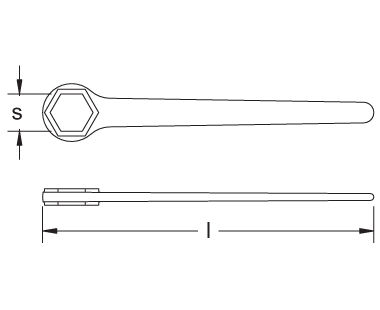

Specifications Table

| Standard Sizes | ||||

| No. | Material | s

inch |

l

inch |

Wt.

lbs. |

| Ex204-005UA | Aluminum Bronze | 11/16 | 6-9/16 | 0.26 |

| Ex204-005UB | Copper Beryllium | 11/16 | 6-9/16 | 0.26 |

| Ex204-010UA | Aluminum Bronze | 3/4 | 6-9/16 | 0.42 |

| Ex204-010UB | Copper Beryllium | 3/4 | 6-9/16 | 0.42 |

| Ex204-015UA | Aluminum Bronze | 7/8 | 9-9/16 | 0.71 |

| Ex204-015UB | Copper Beryllium | 7/8 | 9-9/16 | 0.71 |

| Ex204-020UA | Aluminum Bronze | 15/16 | 9-9/16 | 0.71 |

| Ex204-020UB | Copper Beryllium | 15/16 | 9-9/16 | 0.71 |

| Ex204-025UA | Aluminum Bronze | 1 | 9-9/16 | 0.77 |

| Ex204-025UB | Copper Beryllium | 1 | 9-9/16 | 0.77 |

| Ex204-030UA | Aluminum Bronze | 1-1/16 | 9-9/16 | 0.84 |

| Ex204-030UB | Copper Beryllium | 1-1/16 | 9-9/16 | 0.84 |

| Ex204-035UA | Aluminum Bronze | 1-3/16 | 10-3/4 | 1.10 |

| Ex204-035UB | Copper Beryllium | 1-3/16 | 10-3/4 | 1.10 |

| Ex204-040UA | Aluminum Bronze | 1-1/4 | 10-3/4 | 1.37 |

| Ex204-040UB | Copper Beryllium | 1-1/4 | 10-3/4 | 1.37 |

| Ex204-045UA | Aluminum Bronze | 1-7/16 | 12-3/8 | 2.43 |

| Ex204-045UB | Copper Beryllium | 1-7/16 | 12-3/8 | 2.43 |

| Ex204-050UA | Aluminum Bronze | 1-5/8 | 15 | 2.65 |

| Ex204-050UB | Copper Beryllium | 1-5/8 | 15 | 2.65 |

| Ex204-055UA | Aluminum Bronze | 1-13/16 | 16-3/8 | 3.75 |

| Ex204-055UB | Copper Beryllium | 1-13/16 | 16-3/8 | 3.75 |

| Ex204-060UA | Aluminum Bronze | 2 | 16-3/8 | 3.95 |

| Ex204-060UB | Copper Beryllium | 2 | 16-3/8 | 3.95 |

| Metric Sizes | ||||

| No. | Material | s

mm |

l

mm |

Wt.

kg |

| Ex204-17A | Aluminum Bronze | 17 | 165 | 0.12 |

| Ex204-17B | Copper Beryllium | 17 | 165 | 0.12 |

| Ex204-19A | Aluminum Bronze | 19 | 205 | 0.19 |

| Ex204-19B | Copper Beryllium | 19 | 205 | 0.19 |

| Ex204-20A | Aluminum Bronze | 20 | 205 | 0.22 |

| Ex204-20B | Copper Beryllium | 20 | 205 | 0.22 |

| Ex204-24A | Aluminum Bronze | 24 | 240 | 0.32 |

| Ex204-24B | Copper Beryllium | 24 | 240 | 0.32 |

| Ex204-27A | Aluminum Bronze | 27 | 240 | 0.38 |

| Ex204-27B | Copper Beryllium | 27 | 240 | 0.38 |

| Ex204-30A | Aluminum Bronze | 30 | 270 | 0.50 |

| Ex204-30B | Copper Beryllium | 30 | 270 | 0.50 |

| Ex204-32A | Aluminum Bronze | 32 | 270 | 0.62 |

| Ex204-32B | Copper Beryllium | 32 | 270 | 0.62 |

| Ex204-36A | Aluminum Bronze | 32 | 310 | 1.10 |

| Ex204-36B | Copper Beryllium | 36 | 310 | 1.10 |

| Ex204-41A | Aluminum Bronze | 36 | 375 | 1.20 |

| Ex204-41B | Copper Beryllium | 41 | 375 | 1.20 |

| Ex204-46A | Aluminum Bronze | 46 | 410 | 1.70 |

| Ex204-46B | Copper Beryllium | 46 | 410 | 1.70 |

| Ex204-50A | Aluminum Bronze | 50 | 410 | 1.90 |

| Ex204-50B | Copper Beryllium | 50 | 410 | 1.90 |

How to Choose the Correct Alloy for your Application

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

| Zone Compatibility | Fulfill demand in ATEX Directive 94/9/EC for work in Zones 1, 2, 21 and 22 | Fulfill demand in ATEX Directive 94/9/EC for work in Zones 0, 1, 2, 20, 21 and 22 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3%

Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance |

Be: 1.9%

Co + Ni: 0.4% Other: 0.5% Cu: Balance |

Delivery Reach

We deliver throughout North America. From the moment an order is received, our total focus is to ensure deliveries are shipped out as soon as possible and meet the exact specifications requested.

Need Assistance

Not sure how to operate your equipment? Don’t know which model is best for your project? If you have any technical questions, please feel free to call us at 1 (800) 461-1847.